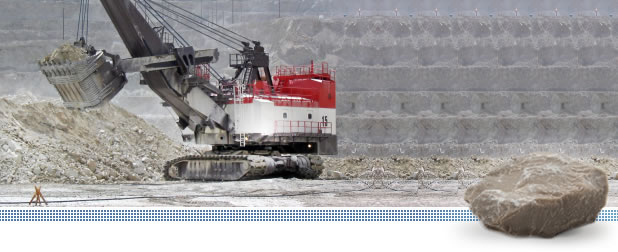

Mining Equipment

Custom Steel Fabrication Services for the Mining Equipment Industry

The Halvorsen Company is a custom steel fabricator for the surface mining industry. We form steel parts and components for mining machines, mining equipment and companies that run mining operations.

We produce components from steel and alloy plate for heavy machinery applications such as heavy duty front shovel buckets for mining machines, mass excavators, wheel dozers, large heavy duty bulldozers, wheel loaders, track loaders and large mining shovels. The Halvorsen Company forms many types of parts that are used to manufacture machines and products used in the surface mining industry. These machines are often used to extract coal, nonmetal minerals such as rock and sand, minerals, ore, metals, rock salt, oil shale, stone and gravel. Halvorsen fabricates parts made from steel and alloy which are assembled to build surface mining machines such as electric rope shovels. We fabricate dipper buckets, dipper doors, bails, equalizers, and handles. We form and bend heavy steel plate to produce components used to manufacture large hydraulic excavators and hydraulic shovels using in the mining industry. At our 2 facilities in Cleveland, Ohio we form steel and alloy parts used to make buckets and beams for large front end loaders. We also form parts used by companies that manufacture draglines, hybrid shovels, mobile mining crushers, surface feeder-breakers, conveyor products and sizers.

The Halvorsen Company is a custom steel fabrication specialist for the mining equipment industry. Since 1955, we have earned an excellent reputation in the mining industry for the quality of the steel and alloy products we build. We understand that high quality workmanship, meeting delivery schedules and value are important to our customers in the mining industry. Our metalworking experience, custom industrial equipment fabrication services, specialized equipment and heavy steel fabrication capabilities are just a few of the reasons why mining equipment businesses rely on Halvorsen to complete their steel fabrication projects on time.

If your company is in the mining equipment industry and you would like more information or want to get an estimate or quote for custom steel fabrication services, call 1-800-423-7080 and ask for Justin Frick or a Sales Engineer or email sales@halvorsenusa.com.

Key steel fabrication services that we perform for mining equipment companies include CAD design, plate bending, mechanical engineering, manufacturing of wear resistant components, plate rolling, plate forming, metal forming, cold forming, hot forming, steel plate fabrication, welding, heat treating, plate cutting and plate straightening. The Halvorsen Company has become a valued supplier of steel and alloy fabrication and design services for the mining industry in the Midwestern United States.

The Halvorsen Company processes a variety of steel and alloy materials for the mining industry including stainless steel, carbon steel, carbon alloy, nickel alloy, aluminum, copper, brass, heat resistant alloys, corrosion resistant alloys, abrasion resistant alloys, non-ferrous steel and chrome carbide overlay plates.

We provide mine supply operations and mining equipment manufacturers with custom steel manufacturing, metal fabricating, flame cut steel parts, custom equipment and custom component solutions. The quality standards of our close tolerance steel and alloy ASME code fabrications are the highest in the mining industry. Our engineers and fabricators can work from your plans, drawings or CAD designs. We can also provide complimentary design and engineering services to build the parts, components or equipment that meet your specific fabricating requirements. We use a variety of techniques and equipment to complete projects for the mining industry including laser and plasma cutting, heat treating, heavy plate rolling and welding, long press brake forming, contour beveling, and hot and cold forming.

The steel fabrications and heavy machinery components we produce are used in the mining and excavation markets to extract valuable minerals and materials through surface mining and sub-surface (underground) mining throughout the United States.

For more information about the services that we provide to mining operations,

aggregate equipment manufacturers, and mining equipment suppliers, please click on one of the following links; Press Brake Forming and Bending, Custom Fabrication Services, Design, Engineering, CAD Drawings and Material Selection, Component and Pressure Vessel Repair Services, Welding and Weld Repair, Heat Treating, Stress Relieving, Normalizing and Annealing, Plate Burning, Shearing, and Beveling, Plate Flattening, Straightening and Cutting, Plate/Component Blasting and Painting, Testing, Inspection and Metallurgical Services, and Machining.

To get an estimate for custom steel fabrication services for your mining operation or mining equipment manufacturing company, to submit a design or CAD drawing, request a quote or submit an RFQ, ask a sales engineer a question, discuss your current project, place a fabrication order or to schedule a tour of our facilities, please call 1-800-423-7080 and ask for Justin Frick or a Sales Engineer or email sales@halvorsenusa.com.