Oil and Gas Refineries

Pressure Vessel and Separator Fabrication and Manufacturing For The Oil and Gas Production Industry and Refineries

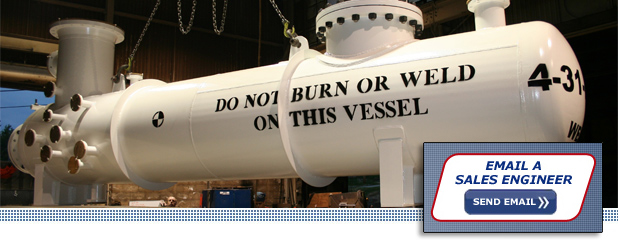

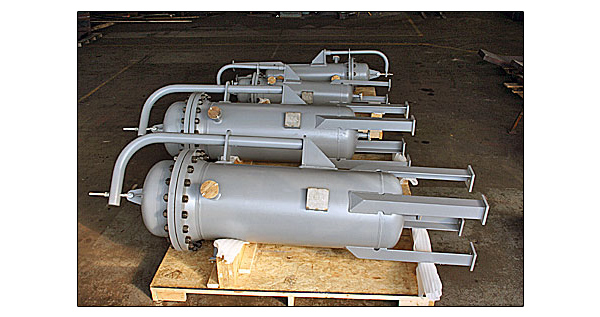

The Halvorsen Company fabricates pressure vessels and separators and provides manufacturing support for oil and gas refineries and the oil and gas industry. The Halvorsen Company is a custom steel fabrication specialist for oil and gas refineries. Since 1955, we have earned an excellent reputation in the oil and gas refining industry for the quality of the steel and alloy products we build. We understand that high quality workmanship, meeting delivery schedules and value are important to our oil and gas refinery customers. Our metalworking experience, custom industrial equipment fabrication services, specialized equipment, heavy steel fabrication capabilities, and ASME code pressure vessel design, engineering and manufacturing services are just a few of the reasons why oil and gas refinery businesses rely on Halvorsen to complete their steel fabrication projects on time.

The Halvorsen Company engineers and designs pressure vessels for oil and gas refineries in concert with our pressure vessel fabrication and manufacturing services.

If your company is in the oil and gas refining industry and you would like more information or want to get an estimate or quote for custom steel fabrication services or ASME code pressure vessel manufacturing services, call 1-800-423-7080 and ask for Justin Frick or a Sales Engineer or email sales@halvorsenusa.com.

Key steel fabrication and construction services that we perform for oil and gas refinery equipment manufacturers and companies include CAD design, plate bending, mechanical engineering and manufacturing of oil/water/gas separation equipment. We custom fabricate the following types of vertical and horizontal ASME equipment for oil and gas refineries:

- ASME Code Compliant Pressure Vessels and ASME Section VIII, Division 1 and 2 Pressure Vessels

- Oil Production Separators

- Thick-Walled Pressure Vessels That Serve to Separate the Crude Oil, Natural Gas and Water

- Stainless Steel Pressure Vessels

- Cylindrical Pressure Vessels That Dehydrate Natural Gas

- Speciality Pressure Vessels Designed to Maximize Utilization and Production of Diesel and Gasoline

- Amine Carbon Filters

- Oil and Gas Separators

- Pig Launchers and Receivers

- Pressure Piping Systems

- Knockout Vessels, Free Water Knock Out (FWKO) Vessels, Knock-Out Drums and Knock-Out Pots (Vapor–Liquid Separators)

- Flash Chambers and Flash Drums

- Expansion Vessels

- Fractionation Towers

- Gunbarrel Tanks

- Expansion Separators

- Cartridge Filters

- Steam Strippers, Stripper Towers and Stripper Columns

- Slug Containment Equipment and Slug Catchers

- Pressure Control Vessels

- Multi-Chamber Horizontal Induced Gas Floatation Units

- Gas Filter Separators

- Oil Dehydration Equipment

- Flowback Equipment

- Standard Vertical ASME Code or Non-Code Heater Treaters

- Multi-Cyclone Gas Separators/Scrubbers

- Carbon Filter Separators

- Clad Vessels

- High Pressure Vessels

- Treator Vessels

- Semi-Elliptical Heads and End Caps For Vessels and Tanks

- ASME Pressure Vessel Dished Heads Including Ellipsoidal Heads, Hemispherical Heads and Torispherical Heads

- Cladded Vessels Including Stainless Steel Strip Cladding

- Heat Exchanger Shells

- Sand Traps and Horizontal and Vertical Sand Separators

- 2-Phase (Oil-Water) Separators

- 3-Phase (Oil-Gas-Water) Separators

- Produced Water Treatment Equipment

- Hydrocyclone Separators

- Gas Scrubbers

- Surge Drums for Hydrocarbon Separation

- Settler Vessels (Pressure Vessel Separators)

- Amine Flash Tanks, Amine Contactors/Absorbers

- Liquified Gas Storage Vessels and Tanks

- Expansion Tanks

- Code Vessels

- Temporary Conical, Tee Type and Y Type Strainers

- Gas/Liquid Separators

- Skid Packages

- Basket Strainers/Filters

- Boilers

- Process Equipment

- Storage Vessels

- Reactors

- Pressurised Columns for the Petrochemical, Petroleum and LNG (Liquid Natural Gas), Shale Oil and Shale Gas Industries

- Coalescers

- Piping Systems

- Petrochemical Tanks (Atmospheric and Pressure)

- Low Pressure, Medium Pressure and High Pressure Oil and Gas Separators

- Test Separators

We provide the following services for oil and gas refineries and petrochemical plants;

- Pressure Equipment Engineering and Drafting

- Vessel Design

- Steel, Alloy and Stainless Steel Plate Rolling

- Steel, Alloy and Stainless Steel Plate Forming Both Hot and Cold

- Ultra-Heavy Plate Forming For Pressure Vessels

- Oil and Gas Component Manufacturing

- Steel, Alloy and Stainless Steel Plate Fabrication

- Steel, Alloy and Stainless Steel Welding and Assembly Welding

- ASME Code Fabrication and Machining

- Design, engineering, fabrication, delivery and erection of separators, pressure vessels and steel tanks for for oil and gas terminals, refineries, terminals and storage and production facilities.

- Heat Treating

- Plate Cutting

- Stress Relieving

- Sandblasting and Coating

- Plate Straightening

The Halvorsen Company has become a valued supplier of steel and alloy fabrication and design services and custom built ASME code compliant oil and gas pressure vessels for refineries. We provide custom built-to-order tanks and custom fabricated refinery grade steel and alloy shells, cones, cylinders and segments for refineries and refinery equipment manufacturers throughout the Midwestern United States.

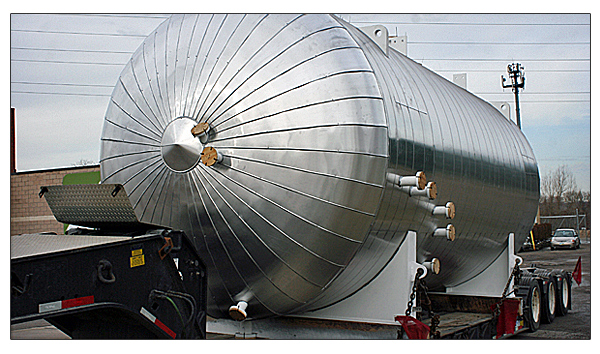

We also handle the logistics for the safe delivery and transportation of the pressure vessels and separators to the field site or refinery. We specialize in fabricating, constructing and manufacturing pressure vessels for oil refineries, natural gas processors and other oil and gas companies that utilize and produce oil, gasoline, butane, ammonia, chlorine, LPG, propane and diesel fuels. The vessels, tanks, separators and other equipment we custom fabricate for oil and gas production are built tough because the harsh conditions involved in oil and gas production require high quality workmanship. The pressure control equipment we build in Cleveland, Ohio will withstand high temperatures and high pressures at on-shore oil and natural gas extraction/production facilities.

The Halvorsen Company processes a variety of materials for the oil and gas refining industry including stainless steel, carbon steel, carbon alloy, nickel alloy, aluminum, copper, brass, heat resistant alloys, corrosion resistant alloys, abrasion resistant alloys, non-ferrous steel and chrome carbide overlay plates. The Halvorsen Company uses a wide range of pressure vessel quality (PVQ) steel plate to fabricate, manufacture and produce welded pressure vessels, boilers and other high pressure applications. The materials we use include the following:

- PVQ516 (Grades 55, 60, 65, 70)

- Carbon Steel

- ASTM A516-70 Plate

- HIC-Resistant Steel

- A-36/SA-36

- Stainless Steel

- T-1 Steel Plate

- Chrome Molybdenum Steel

- A514 Steel Plate

- Nickel Alloys

- SA-516-70/SA-516-70N Steel Plate

- Corrosion Resistant Alloys

- SA-514/SA-517 Steel Plate

- Duplex and Super Duplex Steels

- A516/70 Steel Plate

- Aluminium

- Clad Materials

- C-1045 Steel Plate

The PVQ steel plates that we use can be normalized or stress relieved. We use PVQ steel because it posseses excellent welding capabilities. The Halvorsen Company fabricates boilers and pressure vessels and their accompanying forgings with pressure vessel quality steels that also exhibit outstanding notch toughness.

We provide oil and gas refineries, along with oil and gas refinery equipment manufacturers with custom heavy steel manufacturing, metal fabricating, stainless steel fabrications, flame cut steel parts, ASME pressure vessel code (BPVC) construction services, custom refinery equipment and custom refinery component solutions. The quality standards of our close tolerance steel and alloy ASME code fabrications are the highest in the oil, gas and petroleum refining industry.

Our engineers and fabricators can work from plans, drawings or CAD designs supplied by an oil or gas refinery or from an oil, petroleum or gas refining equipment manufacturer. We can also provide design and engineering services to build the parts, components or equipment that meet your specific fabricating requirements. We use a variety of techniques and equipment to complete projects for the refining industry including laser and plasma cutting, heat treating, heavy plate rolling and welding, long press brake forming, contour beveling and hot and cold forming.

The steel fabrications and components we produce are used in refining operations and the oil, gas and petroleum refining markets throughout the United States.

For more information about the services that we provide to oil and gas refineries and oil and gas refinery equipment manufacturers, please click on one of the following links; Press Brake Forming and Bending, Custom Fabrication Services, Design, Engineering, CAD Drawings and Material Selection, Component and Pressure Vessel Repair Services, Welding and Weld Repair, Heat Treating, Stress Relieving, Normalizing and Annealing, Plate Burning, Shearing, and Beveling, ASME Pressure Vessel Code (BPVC) Construction, Plate Flattening, Straightening and Cutting, Plate/Component Blasting and Painting, Testing, Inspection and Metallurgical Services, and Machining.

To get an estimate for custom steel fabrication services or ASME code pressure vessel fabrication services for your oil and gas refining operation or equipment manufacturing company, to submit a design or CAD drawing, request a quote or submit an RFQ, ask a sales engineer a question, discuss your current project, place a fabrication order or to schedule a tour of our facilities, please call 1-800-423-7080 and ask for Justin Frick or a Sales Engineer or email sales@halvorsenusa.com.